Complex Materials

The heart of research in complex materials group is in unfolding nature’s beautiful trick as a complex system, and in deploying it to redefine our current material design practices.

Nature is an exquisite designer of materials. Trees in the forest and soft tissues of our human body are such examples. Starting from a simple building unit, nature configures it into highly hierarchical structures, step by step, such as a chain of molecules, fibrils, and fibres, each of which are networked. Seemingly simple interactions between parts give rise to amazing collective behaviour, and these units are self-assembled, resulting in intricately designed structures with multi-functionalities. Not overdesigned, not underdesigned, and sustainable!

The heart of research in complex materials group is in unfolding nature’s beautiful trick as a complex system, and in deploying it to redefine our current material design practices.

Research Areas

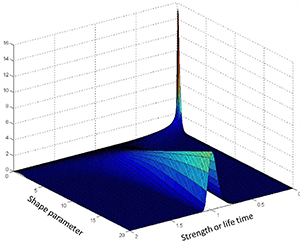

1. Stochastic failure of complex materials

Many materials often show extreme scatters of creep and fatigue strength, but not of normal strength. There is an interesting red thread between them, and it is a similar law to the one governing the ageing of both materials and animals.

- Mattsson, A. and T. Uesaka, Time-dependent, statistical failure of paperboard in compression, in Advances in Pulp and Paper Research, Transactions of the 15th Fundamental Research Symposium, S.J. I'Anson, Editor. 2013.

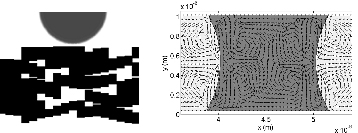

2. Mechanics and structure evolution of fibre networks

Human's process of creating fibre networks, such as papermaking, is fine art, in spite of seemingly simple processes. Today's computational mechanics tools reveal unprecedented level of details that are taking place in micron-scales.

- Lindström, S. and T. Uesaka, Simulation of the motion of flexible fibres in viscous fluids. Physics of Fluids, 2007. 19(113307): p. 1-16.

- Kulachenko, A. and T. Uesaka, Direct simulations of fibre network deformation and failure. J. Mechanics of Materials, 2012. 51(8): p. 1-14.

3. Microfluidics in random porous media

When a tiny fluid meets a random porous media, interfacial forces play significant roles that are not expected in a normal environment. The fluid becomes like an elastic gel or a sticky adhesive, depending on the time-scale in question.

- Holmvall, M., F. Drolet, T. Uesaka, and S. Lindström, Transfer of a Microfluid to a Stochastic Fibre Network. J. Fluids and Structures, 2011. 27(7): p. 937-946.

- Wiklund, H.S. and T. Uesaka, Simulations of shearing of capillary bridges. J. Chemical Physics, 2012. 136(094703): p. 1-9.

4. Instabilities in industrial systems

In industrial environments, disturbances and non-uniformity are everyday matter. However, such occurrences can suddenly trigger disastrous or annoying events, such as web breaks, and web buckling. The underlying mechanisms are now beginning to emerge.

- Edvardsson, S. and T. Uesaka, System dynamics of the open-draw with web adhesion: Particle approach. J. Applied Mechanics, 2010. 77(021009): p. 1-11.

- Kulachenko, A., P. Gradin, and T. Uesaka, Basic mechanisms of fluting formation and retention in paper. J. Mechanics of Materials, 2007. 39(7): p. 643-663.

5. Quantitative microscopy

Seeing is believing, but measuring is more convincing. Advanced microscopy analyses, in combination with computational method, are a powerful tool for quantitatively characterising structures of complex materials.

- Dahlstrom, C., R. Allem, and T. Uesaka, New method for characterising paper coating structures using argon ion beam milling and field-emission scanning electron microscopy. J. Microscopy, 2010. 241(2): p. 179-187.

6. Novel materials by hierarchical design

Hierarchical structures of cellulosic materials offers plenty of opportunities for novel material developments: one can produce cellular materials by "origami", one can make a super low-density 3D foam by foam forming, or one can combine its cellulose nano-fibril with graphene to make bio-composites with an electric functionality.