Printed Sensor Systems

The research group Printed Sensor Systems develops an inkjet printed humidity sensor. Researchers are evaluating different coatings applied on plastic substrates to promote inkjet printing quality of conductive nano particle inks.

The printed sensor group works with the development of printed sensors, investigation of the physical properties of ink and substrate interaction as well as RFID technology and system integration. The main manufacturing method is ink-jet printing, but also flexo and screen printing are used as well as aluminum foil patterns. The inks used are mostly nano-particle inks.

The research activities include:

Development of printed sensors

As the cost of sensor technology decreases, the usage will spread to new market segments, including business areas with products that never before have carried such functionalities. For example, sensor technology is now used for cellulose-based products for packaging, hygiene, or graphical use. By developing printed sensors new functionality can be realized to a very low production cost. Also the sensors can be manufactured directly on packages and other graphical products.

Different ink-jet printed humidity sensors

Resistance change of printed humidity sensors at different humidity levels

RFID technology

Research is carried out both in system integration and applications as well as theoretical studies on antenna properties. RFID tags manufactured on paper substrate have been evaluated. A recent activity is research of how to integrate sensors together with NFC technology

RFID tag on paper where the conductive lines, antenna and capacitive sensor are printed with silver nano particle ink. The microcontroller, FID circuit and battery are mounted using anisotropic conductive tape.

A so called Electronic Article Surveillance tag, usually used in shops on goods as anti theft alarm have been modified to be used with sensors

Hybrid printed electronics

Many electronic components can already today be manufactured by printing. However, the functionality of even the most inexpensive microcontroller or other integrated circuit is for the foreseeable future out of reach by means of fully printed components. Therefore, it is of interest to investigate hybrid printed electronics, where regular electrical components are mounted on flexible substrates to achieve high functionality at a low cost.

Fully functioning Arduino circuit assembled on printed circuit board

Scanning Electron Microscopy picture showing the cross section of a resistor mounted with conductive glue on paper

Investigation of ink and substrate interaction

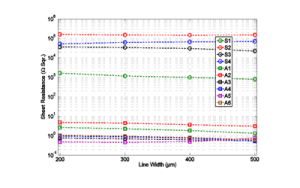

The conductive nano-particle inks used consists of metallic nano particles capped in polymer shells to impede coalescence in the solution. After printing these particles are still encapsulated in polymer shells, which impedes conductance. Research is performed to understand sintering of such ink to improve the conductance, which is important for printed circuits. Also the effect the substrate, such as paper, has on the ink is investigated, and it has been found that different coating content affects the resistance of printed structures. This can be used to design sensors and to choose substrate for printing circuits on.

Plots showing sheet resistance of silver nano particle ink structures printed on different paper substrates

Atomic force Microscopy picture showing silver nano particle ink printed on four different substrates (left to right)