Modeling of resistance welding

Resistance welding is a widely used process of joining metal sheets in automotive and other industries. Resistance welding process comprises of electric, thermal and mechanical phenomenon, which makes this process complex and highly non-linear. The versatility, rich mathematical formulations and robustness of finite element methods make them attractive for simulations of a wide range of problems.

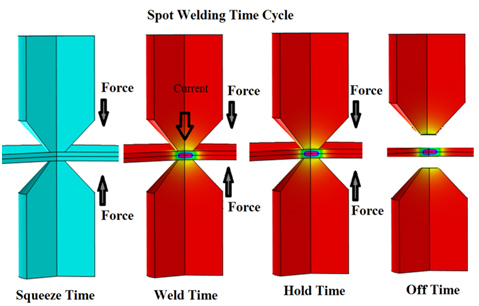

In resistance spot welding process the high magnitude current flow through the welding electrode and causes a localized in the parts to be welded. A pressure is exerted during the process to hold the parts to be welded during welding time cycle.

The developed model can be used for selecting the appropriate welding parameters to produce good welding nugget for different sheet thickness.

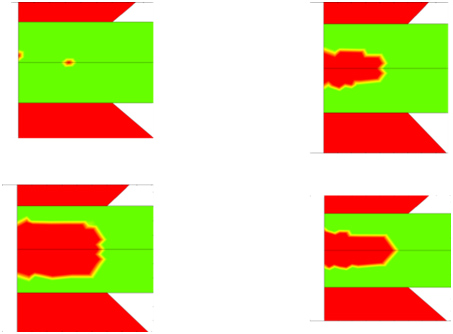

Weld Nugget Formation at different time instances.

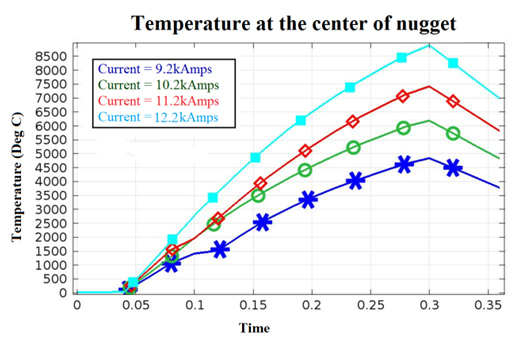

Temperature observed at the center of the weld nugget.

Ongoing Activities

- 3 Dimensional Model for Seam Welding Process.

- Develop 2D Model for Sopt Welding Aluminium Sheets.