Detectors for Thermal Neutrons

The basis of this work is that solid state detectors will replace the 3He filled gas detector now in use, caused by the low world production of 3He gas. The 3He gas detector has the drawback caused by the access of 3He is limited. 3He is produced by a radioactive decay of tritium. Tritium has not been in production since 1988 in US. US produce 8000 liter/year of 3He from a stock of tritium.

In contrast, the demand of 3He is 22000 liter/year just for security application in US, therefore an alternative detector solution is needed. The structure of the neutron converter must be made so efficient that an efficiency of about 30% is reached and without any serious stress induced in the detector. The stress can result in a high leakage current and increased density of recombination centers, which increase the noise and lower the charge collection efficiency.

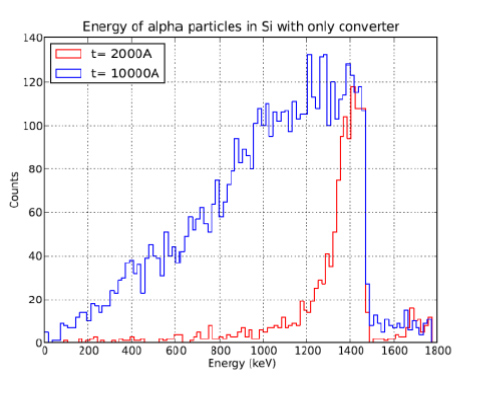

TiB2 was deposited by electron evaporation on a planar silicon detector to investigate the possibility to use it as a neutron converter layer. Figure 3 shows a schematic sketch of the structure and in figure 4 is the simulated response of the generated alpha particles shown for two different thicknesses.[1] From figure 4 it is clear that a thicker layer does not improve the sensitivity with respect to the count rate for a defined spectral peak. Instead the peak is broadened caused by the stopping of the alpha particles in the converter layer.

Simulated structure of a detector with neutron converter.

Comparison of two alpha spectra simulated with 2000 Å and 10 000 Å TiB2 layer thicknesses energy.

Detector response of the produced alpha particles and 7Li nuclei from a converter layer with thicknesses of 2000Å, fabricated in MIUN's clean-room.

Energy calibrated P/H spectra measured on a detector with converter layer using the CMI’s neutron source.