Transformers/Inductors for high frequency power converters

Due to the increased technical requirements of the Switch Mode Power Supplies (SMPS) in applications such as palm top computers, LCD monitors, Laptop adapters and iPads, there is a need for the low profile, high compactness, high power density and highly energy efficient magnetics (inductors/transformers).

Since there exist several challenges in the planar magnetics as the operating frequencies are increased from few hundred kHz to MHz such as the increased core losses (hysteresis and eddy current), winding losses due to skin and proximity effects, unbalanced magnetic flux distribution, increased dielectric losses and stray capacitances and so on….there is a requirement for the careful design of these transformers/inductors at these higher operating frequencies.

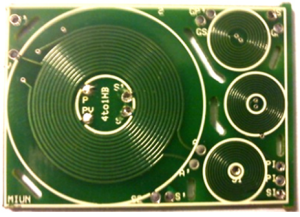

In this regard, in Mid Sweden University the research has been focused on the design and analysis of the high frequency planar transformers/inductors in 1 – 10MHz for the power transfer applications in the load power range of 10 – 70W useful for the above mentioned consumer applications. In order to completely eliminate the core losses of the transformer, initially several coreless PCB step-down transformers of different turn’s ratio and signal transformer/PCB inductors have been designed and evaluated in various converter topologies. One of the coreless PCB transformer modules of 4:1 turn’s ratio along with the signal transformer and PCB inductors is shown in fig.1 along with the power transformer energy efficiency and the thermal profile. The tested power density of the power transformer at the frequency of 2.6MHz is 16W/cm2 with the peak energy efficiency of 95%.

Fig.1 Power/Signal Transformer with PCB inductors, Energy efficiency and thermal profile of Power Transformer at 20W.

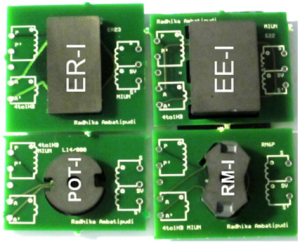

In order to further increase the power density and energy efficiency of the transformers at higher operating frequencies, several core based transformers (POT, ER, EE and RM cores) for power transfer applications have been designed with the available high frequency core materials such as NiZn and MnZn and are shown in fig. 2. One of the novel high frequency planar transformers energy efficiency as a function of load power at a frequency of 3MHz is illustrated in fig.3 and its corresponding thermal profile at the maximum tested power of 50W is illustrated in fig.4. The power density of the corresponding transformer is reported to be 47W/cm3.

Fig.2 Core based POWER transformers.

Fig.3 Efficiency of POT core transformer.

Fig.4 Thermal profile of POT core transformer at 50W.