Project period: 2015-2017

Partners: Valmet AB, SCA Forest Products AB, Stora Enso Research AB.

Project leader: Gunilla Pettersson

Researchers: Hans Höglund, Per Engstrand, Magnus Norgren, Sven Norgren, Staffan Nyström, Jan-Erik Berg.

Summary: One way to increase the export value for the Swedish forest industry of wood based paperboard by means of sustainable development, is to use more of fibre materials produced at high yield (>90%) as in chemimechanical pulping (CTMP) processes. In Sweden; spruce is by far the most common wood species as raw material in production of CTMP for manufacturing of paperboard. CTMP is also manufactured from hardwoods (aspen and birch) as market pulp but is so far not commonly used as a component in high quality paperboards. However, especially birch fibres have some morphological advantages in comparison to softwood fibres, which might be possible to take advantage of.

The project goal is to develop and demonstrate technologies, which will make it favourable to use high yield pulps, (HYP), as low energy chemimechanical pulp CTMP based on hardwoods, particularly birch, in manufacturing of high quality paperboard. The total energy consumption in refining of such hardwood CTMP should be lower than 700 kWh/ton, to be compared to about 1200 kWh/ton in standard CTMP manufacturing from birch at yield >90%. The CTMP should preferably be used in middle plies in paperboards, which will offer opportunities to reduce grammage at given bending stiffness and improve brightness as well as surface smoothness in final products in comparison at use of softwood CTMP. The extractives of birch CTMP should be reduced to such a low level that they do not cause any problems regarding taste and odour.

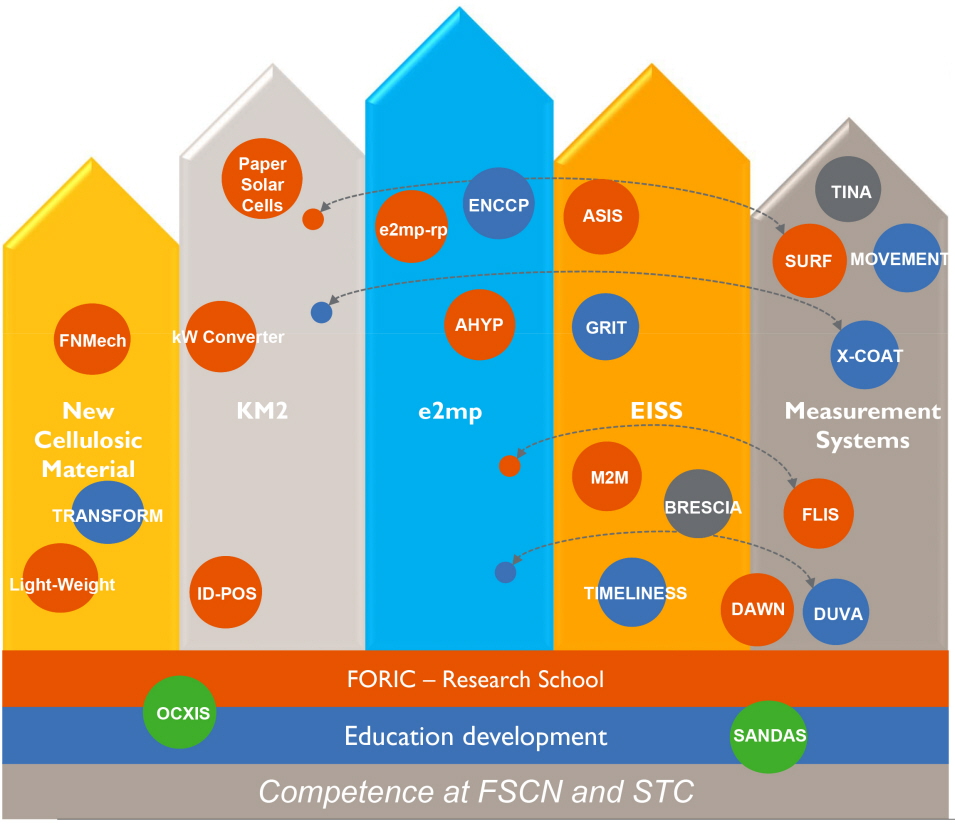

Research actions in Transformative Technologies

All research projects within Transformative Technologies are conducted in co-production with the industry and follows the vision Transforming the Industrial Ecosystem. Here is a brief description of our strategic actions and research actions that is funded by the Knowledge Foundation.

Our six strategic actions connect the research environments at our research centres STC and FSCN. The strategic actions are:

- e2mp - Energy Efficient Mechanical Pulping

- FORIC - Forest as a Resource Industrial College

- EISS - Embedded Industrial Sensor Systems

- KM2 - Large functional electronic surfaces

- Measurement Systems

- New cellulosic materials

In alphabetical order

AHYP - Advanced HYP for paperboard

ASIS - Autonomous Sensors for Industrial Wireless Sensor Networks

Project period: 2015-2019

Partners: ABB Corporate Research, Bosch Rexroth, Shortlink AB.

Project leader: Bengt Oelmann

Researchers: Sebastian Bader, Mikael Gidlund, Muhammad Imran, Mattias O’Nils.

Summary: ASIS is addressing the challenges of making the wireless sensor network technology competitive in relation to wired networks with respect to reliability, predictability, communication performance, and maintainability. Three research issues in wireless network communication, in sensor processing, and energy harvesting will be addressed in a coordinated manner to advance the field of wireless sensor network technology. The overall research question is formulated as: Can autonomous wireless sensor networks, fulfilling the requirements of industrial applications, be designed? And if not, which are they key issues to address in research in order to succeed?

DAWN - Data Analytics in (Wireless) Industrial Networks

Project period: 2015-2018

Partners: Umetrics AB, Bosch Rexroth, ServaNet AB, and Dewire AB

Project leader: Tingting Zhang

Researchers: Stefan Forsström, Mikael Gidlund

Summary: In 2020, about 75 billion different devices to be connected to the Internet and together they make the so-called Internet of Things. The process industry can really take advantage of the increased data availability in terms of both productivity and energy efficiency. In this project, researchers will focus on the development of data analysis system for large-scale sensor networks. The aim is to increase capacity for the industry's data management by developing new data mining algorithms and integrating data analysis with the Internet of Things platform, SensibleThings, developed at Mid Sweden University.

DUVA - Detector and method development in the UV and EUV wavelength region, for application in processing industries

Project period: april 2016 - mars 2019

Partners: Sitek Elektro Optics AB, PulpEye AB

Project manager: Docent Göran Thungström

Researchers: Prof. Christer Fröjdh, Lektor Börje Norlin, new PhD student

Description: The challenge is to develop a method for measurement of optical response signals in the ultra violet (UV) wavelength range to define properties of the fibrilled cellulose fibre. The optical processes involved in the measurement method are transmission, absorption, diffraction and scattering, depended nt ofn the properties of measured object. The method is extended to an extreme ultra violet (EUV) radiation field with a wavelength of 13.5 nm to be able to resolve smaller particles.

Sensitive detectors for measuring optical signals as well as detectors for measuring the optical beam position in EUV radiation fields are therefore developed and characterized. The project is carried out in close collaboration with Pulpeye AB, SiTtek Electro Optics AB and MAX-lax Lab.

E2mp - Energy efficient mechanical pulping

Project period: 2011-2017

Partners: Andritz AB (2011-2014), Holmen AB, Metso Paper Sundsvall AB, SCA Forest Products AB R&D Centre, Stora Enso AB, Valmet AB

Project leader: Per Engstrand

Summary: e2mp is a mechanical pulping initiative by Holmen, Norske Skog, SCA, Stora Enso and the Swedish Energy Agency regarding reduction of energy efficiency. Administrated by FSCN, Mid Sweden University.

ENCCP - Eco-friendly engineering of nanocrystalline cellulose for green packaging

Project period: mars 2016 – februari 2019

Partners: Holmen AB, Tetra Pak AB, MoRe Research Örnsköldsvik AB

Project manager: Prof. Armando Cordóva

Researcher: Prof. Per Engstrand

Description: The objective is to employ innovative and state-of the art sustainable engineering of nanocellulosic material for applications in eco-friendly packaging. By extending our fundamental understanding of eco-friendly catalytic surface modification technology of heterogeneous polysaccharides, we can invent new sustainable reactions for functionalization of nanocellulose. Next, the modified nanocellulose can be applied in improving the properties (e.g. increased strength, compatibility, permeability) of packaging materials. Finally, sustainable eco-engineering of the packaging material could further change the properties towards hydrophobicity resulting in “green” packaging materials with sufficient barriers against oxygen, water vapor and microrganisms.

FLIS - Characterization of wood disintegration processes

Project period: 2014-2017

Partners: Andritz Iggesund Tools, Iggesund Paperboard, PulpEye

Project leader: Benny Thörnberg

Researchers: Lisbeth Hellström, Cheng Peng

Summary: The condition of cutting tools used in a wood disintegration process has a large impact on the quality of the products. Today we don’t know how long the intervals for replacement of worn out tools should be. This project aims at gaining knowledge for how process parameters for wood disintegration are related. By using optical techniques, wireless on-rotor sensing and multivariate modeling we want to find out the most feasible and cost efficient way to monitor these parameters online.

FNMech - Fibre network design: Applications to Hygiene Products

Project period: 2015-2017

Partners: SCA Hygiene Products AB, SCA Forest Products AB, SCA Tissue France SA, Nalco Company Naperville

Project leader: Tetsu Uesaka

Researchers: Tetsu Uesaka, Christina Dahlström, Majid Alimadadi, Amanda Mattsson

Summary: In this project we consider fibre network as a micro-mechanical and microfluidics system, and investigate the non-uniform deformation of fibre network and the transport of complex fluids (body fluids) within the network. Such a problem is currently the core issues related to the new product development of hygiene products.

The primary objective of this project is to develop fundamental understandings of the role of fibre network structures and fibre properties in the network deformation and the mass transport, particularly on the microscopic level. Based on this, we plan to develop predictive design criteria and design tools for both processes and products together with industrial partners. We take both theoretical and experimental approaches. On the theoretical side we perform particle-dynamics modeling in order to obtain information on microscopic phenomena of network deformation, fluid flow, and their interactions (multi-phase particle dynamics). On the experimental side, we use confocal microscopy and cryo-SEM analyses of microfluidic phenomena in order to validate the model and to obtain insights of the microscopic mechanisms.

With these fundamental understandings and insights, and predictive design criteria obtained from this project, the industries, which are positioned in the supply chain of this growing healthcare and hygiene market, can accelerate their product developments. Particularly the pulp and paper industries in the region will be able to utilise and promote northern softwood fibres as a competitive edge in the global market by tailoring fibre properties.

Foric - Forest as a Resource Industrial College

Project period: 2014-2021

Partners: SCA Timber AB, Sense Air AB, Ragn-Sells AB, Frontway AB, Sundsvall Energi AB, SCA Forest products AB, Valmet AB, PulpEye AB, Stora Enso Kvarnsveden, Sylvestris AB, Skogforsk AB, MoRe research AB, Mantex AB, Innventia AB

Project leader: Per Engstrand

Summary: FORIC is a new graduate school in close cooperation with the business companies in Sweden where graduate students will increase their competitiveness. Academia and industry will benefit from interacting with each other.

GRIT - Distributed green services on the Internet of Things

Project period: april 2016 – mars 2018

Partners: Dohi Sweden, Prevas

Project manager: Dr. Stefan Forsström

Reference group: Prof. Bengt Oelmann och Docent Leif Olsson (Miun) Antonio Corradi från University of Bologna.

Description: The goal of this project is to enable new types of future IoT applications, with a particular focus on applications that include many participants and thus require large scale information dissemination. It is paramount to solve this if the IoT shall expand beyond the simple applications we see today. This project will however only focus on enabling IoT applications in typical green scenarios, such as large scale environmental monitoring and acting upon large amounts of sensed information to become more environmentally friendly. This in order to fit the length, scope, and resources of a ProSpekt type project.

ID-POS - Large Areas for RFID Identification, Positioning and Interaction

Project period: 2014-2017

Partners: IDAG Design Studio AB, Ovako Tube & Ring AB, Sandvik Materials Technology AB, Skultuna Flexible AB, Sweprod Graphics AB.

Project leader: Johan Sidén

Researchers: Henrik Andersson

Summary: In 2020 there will be up to 50 billion devices connected to the Internet. A growing part of these devices are RFID- and NFC technology. Today a RFID systems have the ability to determine the presence and ID-number of a tag. In this project researcher want to investigate how a RFID system can accurately determine unique position of tags distributed over a specific area or volume. This with RFID reader antennas that is relatively thin but of significantly large area is used to identify and position RFID tags placed upon the reader area.

kW Converters - High Frequency Medium Power Isolated Converters

Project period: 2014-2017

Partners: Saab AB, Elektronikgruppen AB, Powerbox AB, Seps Technologies.

Project leader: Kent Bertilsson

Summary: Mid Sweden University have in a few years reached the research front in high frequency magnetics and converters for power transfer applications in the power levels of 50-100W. This project targeting the medium power level converters (few kW) at high frequency, based on the expertise in the existing research carried out in power electronics group. Together with industrial partners such as SAAB anew, more effective high frequency kW converters will be developed.

Light-weight Structural Composites from Fibre-based Materials, Reliability-based Design

Project period: 2014-2017

Partners: SCA Forest Products AB R&D Centre, Billerud Korsnäs

Project leader: Tetsu Uesaka

Summary:

The project is aiming at developing light-weight composites used for packaging and structural applications from fibre-based materials.

Reduce energy and material

In the materials world, light-weighting is taking place at all fronts. This is because our sustainable society demands less energy, less material, and less water uses. For example, Boeing 777's tail section used to be made from aluminium, but was recently replaced with composites which are lighter, more durable, and more reliable at high altitudes. The result is that it cut the weight of tail section 8000 pounds by 15%, and drastically increased fuel economy. This is also true for packaging materials which are transported and consumed in our everyday life.

The research focus

Our first quest is to investigate typical fibre-based materials, such as paper and board, from the point of durability and reliability. It is often misunderstood that strong materials are automatically durable and reliable in end-use. Our theoretical and experimental studies showed that they are not necessarily so, and also the materials exhibit far more variability that what routine strength tests can predict (Figure 1). "What really control such variability?" and "How to design new structures that imparts excellent reliability?" These are some of the research questions we are posing in our research. In our preliminary study some fibers exhibit very good durability, and some structure drastically reduces variability and thus reliability. We are trying to find new manufacturing conditions and converting conditions that will enhance durability and reliability of fibres as material, together with our industrial partners. Our quest has just started.

M2M Communication - Reliable and Secure M2M Communication in Cyber-Physical Systems

Project period: 2015-2018

Partners: ABB Corporate Research, Vinnter AB and Sundsvall Energi AB.

Project leader: Patrik Österberg

Researchers: Ulf Jennehag, Tingting Zhang, Mikael Gidlund (new Ph.D-student)

Summary: A smart grid network is a cyber-physical system that integrates power infrastructure with information technology. It is anticipated that smart grid networks will use machine-to-machine (M2M) communication infrastructure and advanced control techniques for improved power distribution and management. The wireless M2M business is expected to exceed $136 Billion in revenue by the end of 2018. However, it cannot penetrate the smart grid network market until several key challenges such as reliability, interoperability, scalability, security, and real-time communication have been addressed and solved properly. The scope of this project is to investigate and propose new reliable and secure concepts of M2M communication in smart grid networks and to demonstrate the achieved results in a proof-of-concept demonstration in a real environment. We will approach these challenges applying theory and methods from several different disciplines such as network security, signal processing, control theory, and wireless communication.

MOVEMENTS - Method for cost-optimized volumetric object monitoring systems

Project period: april 2016 – mars 2019

Partners: Vattenfall, Combitech AB, In Situ AB, LFV

Project manager: Assistant professor Najeem Lawal

Researcher: Benny Thörnberg och en ny New Post Doc.

Description: The ability to effectively identify flying objects in a given volume and characterize their activitiescan lead to improved prediction of future activity. Such prediction is applicable, for example, inimproving collision avoidance systems for wind farms. Employing a visual monitoring systemconsisting of many camera nodes that form visual sensor network (VSN) will provide more reliabledatasets compared to a human approach. Effective characterization can be achieved through robustmodels of the activities based on adequate datasets provided by the VSN. In this project we willinvestigate the requirements for VSN node architecture and deployment topology for remote outdoormonitoring. Our aim is to find a cost optimized design for the VSN nodes and topology constrainedlimited resources. These resources include energy, communication and data storage. In this project,we will investigate multi-camera node architecture (MCNA) by exploring trade-offs among theresources and node cost. We will also investigate how MCNA can lead to a cost optimized nodedeployment topology. Through close collaboration with industry partners we will be able to fulfilthe project objectives and provide the industry with a tool for predicting future activity within avolume. Although this proposal focuses on monitoring wind farms and flying birds’ activities, theresult are applicable in other fields.

OCXIS - Master of Science in Operation and change of complex industrial systems

Project period: mars 2016 – februari 2018

Partners: Akzo Nobel Pulp and Performance Chemicals AB, Länsförsäkringar Västernorrland AB, Nordea, Dewire, ÅF Industry AB, SCA Graphic Sundsvall AB, SCA Östrand

Project manager: Researcher Olof Björkqvist

Researchers: Olof Björkqvist, Per Engstrand, Peter Öhman, Ola Lindberg

Description: An education on advanced level can support the transformation of the industrial ecosystems, the TIE Vision, and the adjustment of businesses and industries based on technical systems and business processes. The program is profiled towards process and energy industry, ICT industry and banking, insurance and property companies.

The program is multidisciplinary and consists of three distinct themes: Subject specialization, organization and management and analysis of complex systems. The courses are available for working students and they are also available to be followed by the Mid Sweden University´s program students. The program is developed by four of Mid Sweden University´s research centres; FSCN, STC, CER and DEMICOM.

Paper Solar Cells

Project period: 2014-2016

Partners: Iggesund Paperboard AB, Superior Graphite Europé Ltd, Laser Cut AB

Laser Nova AB, STT Emtec AB, Vesta Si Europé AB, Sol Voltaics AB

Project leader: Håkan Olin

Summary:

Low cost solar cells are needed. Manufacturing processes of today are mainly based on costly vacuum methods making the solar electricity to the most expensive one. Roll-to-roll processing is potentially more efficient as manufacturing method for solar cells.

The challenging question is to develop a system that, if realized on an industrial scale, would allow square-kilometre sized output of solar cells. A simple estimation points to a global need of above 100 000 km2 per year. This will correspond to a market of of 1 TS. Such high output is only available in the paper industry today. Utilizing the highly efficient machinery developed in this roll-to-roll industry for products with higher customer value, such as solar cells and other advanced applications, represent a large opportunity. The paper industry has disappearing economical margins and the industry would benefit from alternative products with higher customer value.

The requirements of such flexible electronics systems are hard to meet with two main challenges: 1. Processing speed above 10 meter per minute including patterning and 2. environmentally friendly materials and processes.

Today, there are several candidates that could meet these requirements such as solutions processing of organic semiconductors (Krebs et al 2009, Sondergaard et al 2012). However with the novel layered semiconductors, which can be found amng the transition metal dichalcogendes (TMDC) a new system is emerging (Q.H. Wang et al 2012). We believe that this TMDC system might be simpler and robust.

There are two objectives with this proposal: The first one is to take the first steps toward establishing a novel approach for flexible electronics based on thin layers of semiconducting TMDC materials. The second one is to use these processing methods to develop simple protoypes of low-cost solar cells using this process. We have made an inventory of possible system that can meet high-speed and environmental requirements and have indentified the combination of:

- Layered materials - semiconducting TMDC and conducting graphene

- Solution based roll-to-roll processes

- Using paper as an environmentally friendly, mechanical stable and low-cost substrate

- Direct writing using layers and flashlight lamps

PlenoCap - Plenoptisk infångning och beräkningsbaserad fotografering

Project period: 2013-2015

Partners: Adopticum, Ericsson AB, LC-Tec, Optronic

Projectleader: Roger Olsson

Summary: Plenocap aims to study and improve the plenoptic camera capture systems, develop methods and algorithms, and investigate their effect on future immersive video communication services.

Robust Wireless Communication in Harsh Radio Environments

Project period: 2013-2015

Partners: ABB, AngloGold Ashanti, Boliden, LKAB, Swedish Connection.

Project leader: Mikael Gidlund

Researchers: Ulf Jennehag, Stefan Pettersson, Tingting Zhang, Patrik Österberg.

Summary: The mining industry is facing a new challenge. There is a global increase in demand for commodities driven by the developing countries. At the same time easy access to high grade ore is decreasing. Increasing the level of automation and improving operational performance is a key to meet these challenges.

SANDAS - Master of Science in sensor and automation systems

Project period: March 2016 – February 2018

Partners: Eurocon AB, ÅF AB, Combitech AB, SenseAir AB, Fiber Optic Valley, Bucher Emhart Glass

Project manager: Assistant professor Claes Mattsson, avdelningschef

Description: A new Master in Sensor and Automations Systems will be developed in collaboration with industrial partner companies. The objective of the proposed project is to transform the current Master’s program into a nationally and internationally relevant and attractive through stronger collaboration with industry and a refined thematic focus. In order to achieve these project objectives, investigation and development of both the program content and teaching methods are necessary. A preliminary investigation has shown that there is currently no second-cycle degree program in Sweden providing all of these competences.

There is an increasing demand in electronics that go beyond standalone systems, which are integrated in other (non-electronic) systems. The Internet of Things, for example, will require electronics to be embedded in a large number of physical objects in order to create interfaces between the object itself and the Internet. In many cases, sensors and actuators will play an important role for the realization of such interfaces.

Student graduating from this program will have thorough knowledge in the field of Sensor and Automation systems. The graduate is expected to have a detailed understanding of sensing principles, sensor design, as well as complex sensor systems, which can include readout, processing and communication subsystems. Moreover, the graduate should obtain knowledge of the use of sensors and sensor systems, for example, within the application field of metrology and automation. The new program will be based on existing modules which will serve as a starting point for the development.

The suggested program will use flipped classroom as pedagogical method. This concept allows the use of ICT supported education in order to provide study material outside the classroom, whereas classroom time becomes can be used for more active learning approaches. Using online material also facilitates integration of students that are part-time employees at a company.

SURF - Surface characterization of industrial large area products

Project period: 2015-2017

Partners: Iggesund Paperboard, BillerudKorsnäs Frövi, BIM Kemi, MoRe Research

Project leader: Jan Thim

Researchers: Mattias Andersson, Anatoliy Manuilskiy, Niklas Johansson.

Abstract summary: The paper- and paperboard industries are undergoing a transition in terms of product specializations. Newspaper is not as much in demand any more, the competition in paperboard products is hardening, forcing the paper- and paperboard industries to start producing new products, where there is even higher demand on surface characteristics, since most products will undergo high quality print. This project will attempt to bridge the gap of modern industrial measurement needs for surface characterizations. We will extract new methods for characterizing surface parameters and to – wherever possible – adapt them for usage online/inline. Together with leading industrial partners we will extract, adapt, optimize and test these methods.

TIMELINESS - Time and mission critical communication in low-power wireless networks

Project period: februari 2016 – mars 2019

Partners: ABB Corporate Research och Analog Devices

Project manager: Prof. Mikael Gidlund

Researchers: Filip Barac, New PhD Student

Description: The modern solutions in industrial wireless communication are currently unable to fulfill the expectations of process automation. The underlying reason is the lack of resilient communication protocols that are able to seamlessly recover from communication outages. Industrial Wireless Sensor Networks (IWSN) are typically expected to maintain a 99.999% (the so-called "five-nines") reliability and delays at most equal to sensor refresh rates, which can be as low as tens of milliseconds. Process automation functionalities served by the IWSN communication range from process monitoring and closed-loop control to mission-critical applications, such as interlocking. Every blackout in IWSN communication leaves the industrial process unattended, which may lead to serious consequences, such as damage of material assets, the environment and even human safety risks. The protocol design is additionally hindered by the dynamics of industrial environments, caused by the changes in the physical layout of the environment, as well as spurious electromagnetic emissions and interference from other wireless systems. Being a challenging area still in its infancy, the IWSN technology has received significant attention in the wireless sensor community. However, the main inhibitors of research efforts are the inability to understand the distinctive features of IWSN with respect to the classical WSNs, and the effects of industrial environments on wireless propagation. Another critical issue in IWSN communication is the perception of link quality. The IEEE 802.15.4 standard stipulates that every compliant device shall provide two hardware-based channel quality indicators for every received packet: Received Signal Strength (RSS) and Link Quality Indicator (LQI). This project will investigate and propose more reliable channel quality indicators and better coexistence mechanisms.

TRANSFORM - New process to produce delignified pulp based on mechanical pulp as raw material

Project period: march 2016 – february 2017

Partners: Stora Enso Kvarnsveden, Valmet AB

Project manager: Prof. Magnus Norgren

Researchers: Prof. Björn Lindman, Dr. Louise Logenius, Prof. Bo Westerlind, Phd-student

Description: In Sweden, an annual production capacity of over 3 million tons of mechanical pulp exists, where a large share is or has been used for the production of paper qualities dedicated to newspapers. For some years, the accelerating trend to move news reporting to the Internet has made the mechanical pulp producers suffer hard from the decreased market demand for newsprint. The goal of the TRANSFORM project is to investigate a new simplified process to produce delignified pulps based on mechanical pulp as raw material and to use choline-based deep eutectic solvents (DESs) for selective lignin dissolution. One expected use of produced semi-chemical pulps would be as reinforcement in other mechanical pulp based qualities. The vision is to ultimately benefit from the investments in refiners and bleaching stages already made in existing mechanical pulp mills. Based on a concept where fibers first are mechanically deliberated at low energy inputs (~100 kWh/t, “Asplund pulp”), the kinetics and degree of delignification for deliberated fibers will be compared with conventional chips treated with DESs. One assumption is that the delignification performed at these mild conditions is radically improved by the increased surface area and accessibility of mechanically deliberated fibers compared with chips treated in the same manner. Furthermore, using DESs issues with selectivity and degradation of cellulose and hemicellulose would be overcome. If this hypothesis is correct, great opportunities to develop rapid, gentle and less capital intensive delignification process is foreseen. Thus, new semi-mechanical pulp qualities with physical and mechanical properties more similar to conventional chemical pulps and certain paper qualities would be possible to produce at lower cost and higher profits. Moreover, possibilities to design a delignification process generating sulfur-free lignin to be used in different applications compared with conventionally obtained kraft lignin, is offered.

X-COAT - Characterisation of layered structures by a combination of X-ray fluorescence and compton imaging

Project period: april 2016 – march 2017

Partners: Mantex AB, Iggesund Paperboard AB, Excillum AB, MoRe Research Örnsköldsvik AB

Project manager: Prof. Christer Fröjdh

Researchers: Jan Andersson, Börje Norlin

Description: X-ray fluorescence is a method to measure the atomic composition of a substance or an object. The object is excited by a primary beam and the fluorescent photons emitted from the object are registered. The depth sensitivity depends mainly on the fluorescence energy of the atoms of interest. In addition the primary beam will undergo Compton scattering. The Compton signal carries information on interior properties of the object and can, for example, be used to find voids in a layered object. The method is targeting paper mills, and can be demonstrated for paper coated with CaCO3 where the depth sensitivity of the method ideally matches the typical coating thicknesses. For a coated paper the signal will be generated from the heavier atoms in the coating and essentially be proportional to the coating weight. In addition Compton scattered photons from the light elements in the kernel will carry information of the thickness of the kernel. The combination of Xray fluorescence and Compton scattering is a general method that will be extended to other applications in future projects.